The automotive front end module (FEM) market is experiencing significant growth as automotive manufacturers look to enhance vehicle safety, performance, and efficiency. These modules are critical components that house various elements of a vehicle’s front-end structure, including the radiator, lighting systems, bumper, grille, and other essential components. As vehicle design evolves to meet stricter safety standards and consumer expectations, the demand for front end modules is expected to rise, particularly in the electric vehicle (EV) and autonomous vehicle sectors.

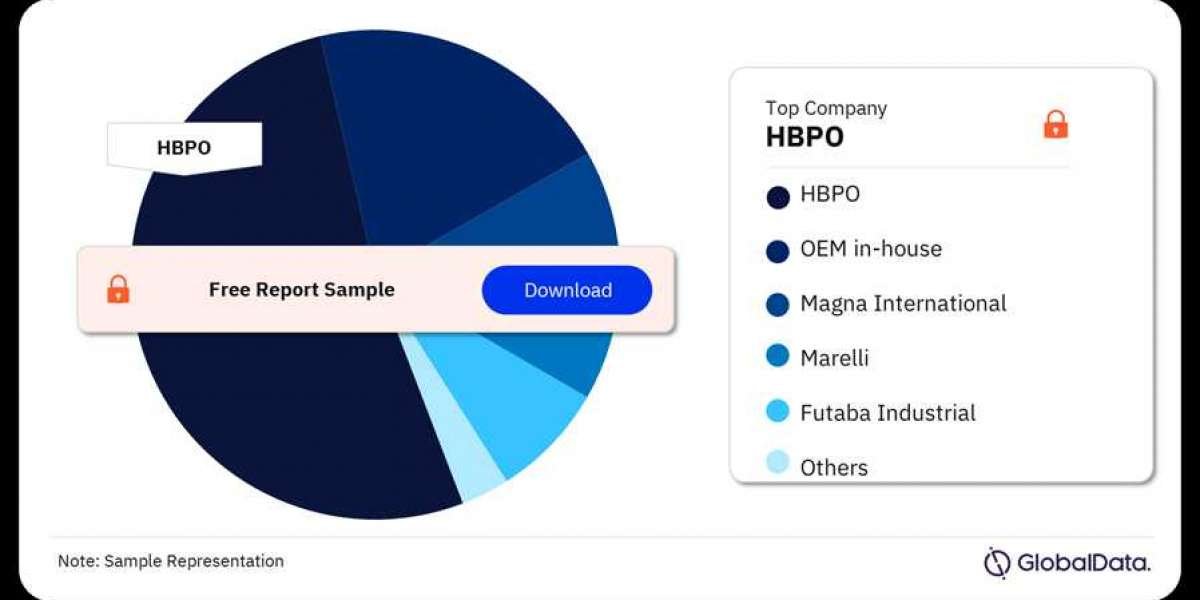

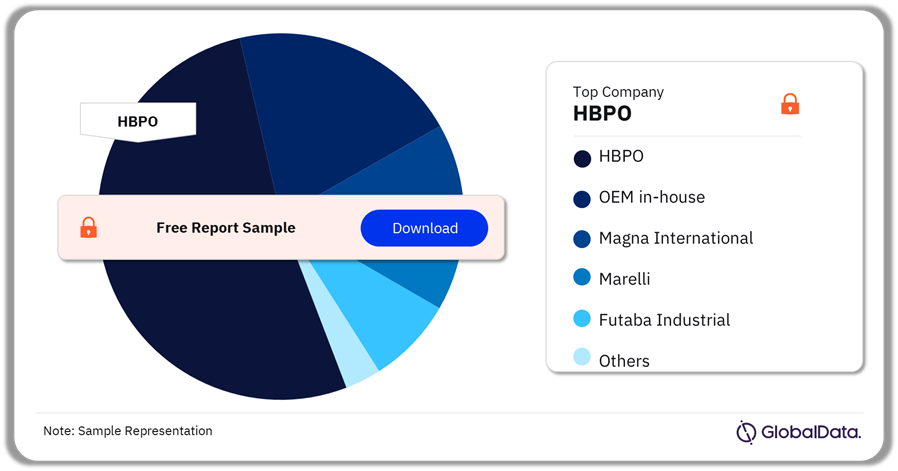

Buy the Full Report to Know More about Major Developments in Automotive Front-End Modules Market Companies Download a Free Report Sample

Key Components of Front End Modules

Radiator and Cooling Systems: The radiator and related components are essential for cooling the engine and preventing overheating. In electric vehicles, this function is also critical for battery management systems.

Lighting Systems: This includes headlamps, fog lights, and other lighting elements. Advanced lighting technologies, such as LED and laser lights, are now commonly used in modern front end modules.

Bumper and Grille: The bumper provides essential safety features during low-speed impacts, while the grille facilitates airflow to cool the engine and enhance the vehicle’s performance.

Crash Protection: FEMs are designed to offer enhanced safety and impact resistance in case of a collision. Front end modules incorporate energy-absorbing materials and structures to minimize damage and injury in an accident.

Market Drivers and Growth Factors

Several key factors are driving the growth of the automotive front end module market:

Increasing Demand for Safety Features As global safety regulations become more stringent, automotive manufacturers are focusing on designing front end modules that enhance crash protection and pedestrian safety. Front end modules now feature energy-absorbing materials and advanced designs that help reduce the impact of collisions.

Advancements in Automotive Design and Lightweighting As automakers aim to improve fuel efficiency and meet stricter emission standards, lightweighting has become a critical focus in vehicle design. Front end modules are increasingly being made from lightweight materials, such as aluminum and composite materials, which help reduce vehicle weight and improve overall fuel efficiency.

Growth of Electric and Autonomous Vehicles The growing adoption of electric vehicles (EVs) and the development of autonomous vehicles are significant contributors to the expansion of the FEM market. EVs, in particular, require sophisticated thermal management systems, which are typically housed in front end modules. Additionally, as autonomous vehicles require additional sensors and cameras, front end modules are being redesigned to accommodate these new technologies.

Consumer Demand for Aesthetic and Functional Designs With rising consumer demand for innovative vehicle designs, manufacturers are increasingly incorporating cutting-edge features such as advanced lighting systems, aesthetic grilles, and unique bumpers. Front end modules play a pivotal role in achieving these design goals, offering automakers the ability to enhance both the functionality and appearance of their vehicles.

Cost-Efficiency and Integration in Manufacturing The use of integrated front end modules in vehicle assembly streamlines production processes. FEMs allow for the consolidation of multiple parts into a single, ready-to-install unit, saving time and reducing assembly costs. This modular approach is particularly beneficial for mass production and has made the manufacturing process more efficient for automakers.

Emerging Trends in the Automotive Front End Modules Market

Integration of Advanced Lighting Technologies Automotive manufacturers are increasingly using advanced lighting technologies, such as adaptive LED headlights, laser lights, and OLED lighting, in their front end modules. These innovations not only improve vehicle visibility but also contribute to the vehicle’s aesthetic appeal. As lighting technologies continue to evolve, front end modules will integrate more intelligent and energy-efficient lighting systems.

Focus on Pedestrian Safety With growing concerns about pedestrian safety, manufacturers are designing front end modules with features that mitigate pedestrian injuries in the event of a collision. These include active bumpers, energy-absorbing materials, and pedestrian detection systems that can automatically apply the brakes if a collision is imminent.

Electric Vehicle (EV) Thermal Management As the popularity of electric vehicles rises, front end modules are becoming integral in managing the thermal requirements of EVs. These modules need to accommodate systems for battery cooling, motor cooling, and cabin air conditioning, all of which are critical for the performance and longevity of electric vehicles.

Incorporation of Autonomous Vehicle Technologies Front end modules in autonomous vehicles are being equipped with additional sensors, cameras, and radar systems to support self-driving technologies. These sensors require precise integration into the front end module to ensure their optimal function and accuracy.

Use of Sustainable and Recycled Materials Sustainability is a growing trend in the automotive industry, and front end modules are not exempt from this movement. Manufacturers are exploring the use of sustainable and recycled materials in FEM production to reduce the carbon footprint of vehicles. This includes the use of bio-based plastics, recycled metals, and composites.

Challenges in the Automotive Front End Modules Market

Rising Material Costs While lightweight materials offer significant benefits, the rising cost of materials such as aluminum, carbon fiber, and advanced composites poses a challenge for automakers. Manufacturers must balance the cost of these materials with the need to meet safety, performance, and fuel efficiency standards.

Technological Complexity As front end modules become more integrated with advanced technologies like sensors and lighting systems, the complexity of their design and manufacturing increases. Ensuring compatibility between various systems and components while maintaining overall vehicle safety and performance is a significant challenge for manufacturers.

Regulatory Compliance As safety and environmental regulations become more stringent worldwide, automakers are facing increased pressure to design front end modules that comply with a growing number of standards. Ensuring compliance with these regulations while maintaining cost-effectiveness can be challenging.