Birch oil is a versatile essential oil extracted from the bark and twigs of birch trees, renowned for its therapeutic properties and aromatic appeal. Widely used in industries such as personal care, aromatherapy, and pharmaceuticals, birch oil offers a range of applications including pain relief, skincare, and stress reduction. With increasing demand for natural and organic products, setting up a birch oil manufacturing plant presents a promising opportunity to cater to the growing market for high-quality essential oils while promoting sustainable sourcing and production practices.

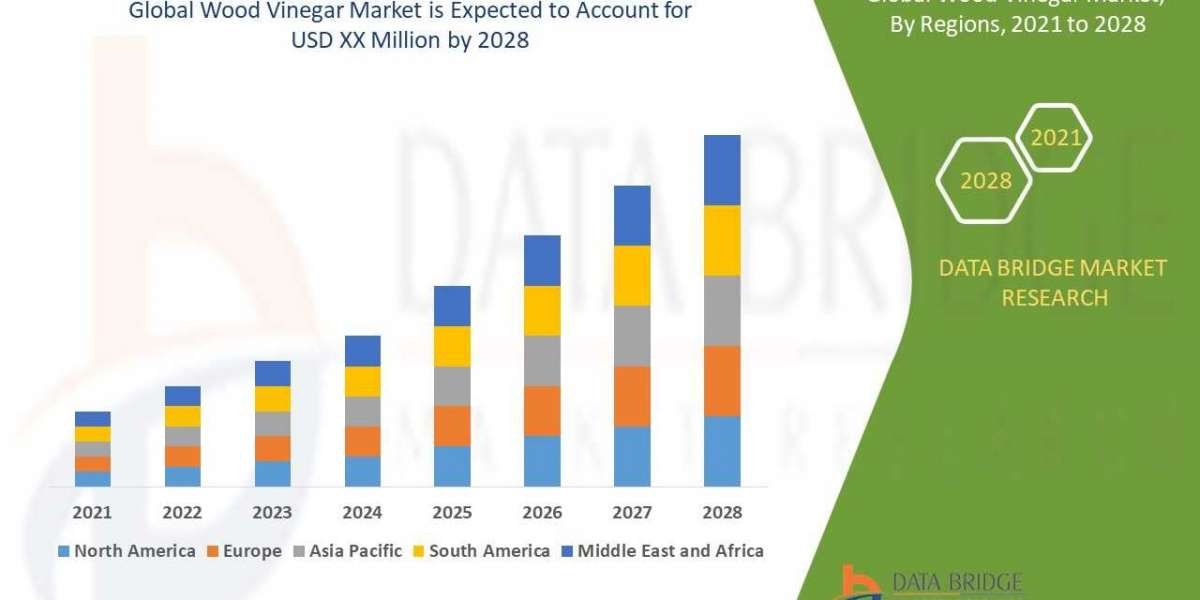

Market Overview

The market for birch oil has been expanding due to the rising popularity of natural remedies and eco-friendly products. Its applications in aromatherapy and cosmetics have gained significant traction, particularly among health-conscious consumers. The growing demand for essential oils in wellness and spa industries further fuels its market growth. Additionally, birch oil is sought after for its anti-inflammatory and antiseptic properties, making it a valuable ingredient in pharmaceutical formulations. As consumers increasingly opt for chemical-free alternatives, the birch oil market holds substantial potential for manufacturers.

Get a Free Sample Report with Table of Contents@ https://www.expertmarketresearch.com/prefeasibility-reports/birch-oil-manufacturing-plant-project-report/requestsample

Manufacturing Process

The production of birch oil involves several steps to ensure quality, purity, and efficiency:

Raw Material Sourcing:

Birch tree bark and twigs are harvested sustainably to ensure consistent availability without harming the environment.Cleaning and Preparation:

The raw materials are cleaned and prepared by removing impurities such as dirt and unwanted particles.Steam Distillation:

The prepared bark and twigs are subjected to steam distillation, a process that extracts essential oil through the application of heat and steam.Oil Separation:

The oil is separated from water and other residues using specialised equipment to achieve high purity.Filtration and Purification:

The extracted birch oil is filtered and refined to remove any remaining impurities, ensuring a premium-quality product.Packaging:

The final product is packaged in dark, airtight containers to preserve its potency and extend its shelf life.Quality Assurance:

Rigorous testing is conducted at each stage to ensure the oil meets industry standards for purity, aroma, and therapeutic benefits.

Key Considerations for Setting Up the Plant

- Location: Choose a site near birch tree sources to minimise transportation costs and ensure a steady supply of raw materials.

- Infrastructure: Invest in advanced distillation equipment, filtration systems, and quality control tools for efficient production.

- Compliance: Adhere to environmental and safety regulations for sustainable sourcing and manufacturing practices.

- Workforce Training: Train employees in the distillation process, quality testing, and safe handling of raw materials to maintain high standards.

Benefits of Birch Oil Manufacturing

- High Demand: Sought after in wellness, aromatherapy, and skincare industries.

- Natural and Sustainable: Appeals to consumers prioritising eco-friendly and chemical-free products.

- Diverse Applications: Used in pharmaceuticals, personal care, and household products.

- Export Potential: Increasing global interest in essential oils creates opportunities for international trade.

Target Audience

The primary consumers of birch oil include:

- Aromatherapy and Spa Industries: Businesses using birch oil for relaxation and therapeutic treatments.

- Cosmetics and Skincare Brands: Companies incorporating birch oil into natural and organic product lines.

- Pharmaceutical Sector: Manufacturers utilising birch oil for its anti-inflammatory and antiseptic properties.

- Export Markets: Distributors catering to international buyers seeking high-quality essential oils.

Challenges and Solutions

- Raw Material Availability: Seasonal limitations in birch tree harvesting can impact production. Sustainable sourcing practices and partnerships with suppliers ensure consistent supply.

- Market Competition: Differentiating products through certifications, superior quality, and unique packaging enhances market competitiveness.

- Consumer Education: Creating awareness about the benefits of birch oil through marketing campaigns can drive adoption.

Marketing Strategies

To establish a strong presence in the birch oil market, manufacturers can adopt the following strategies:

- Collaborations: Partner with aromatherapy and skincare brands to expand distribution networks.

- Digital Marketing: Use online platforms to educate consumers about the benefits and applications of birch oil.

- Trade Shows: Participate in wellness and beauty expos to showcase product quality and engage with potential buyers.

- Eco-Friendly Branding: Highlight sustainable sourcing and eco-conscious production practices to attract environmentally aware consumers.

Sustainability in Manufacturing

Sustainability is integral to birch oil production. Implementing responsible harvesting practices, minimising waste, and using energy-efficient distillation techniques align with global environmental goals. Recyclable or biodegradable packaging further enhances the product’s appeal to eco-conscious buyers, while adhering to sustainable practices ensures long-term access to raw materials and market credibility.

Future Outlook

The demand for birch oil is expected to grow steadily as industries and consumers increasingly prioritise natural and sustainable products. Innovations in distillation techniques, coupled with expanded applications in health and wellness, will further enhance its market potential. By focusing on quality, sustainability, and customer engagement, manufacturers can secure a competitive edge in this thriving market. Establishing a birch oil manufacturing plant represents a valuable opportunity to cater to the growing demand for premium essential oils while contributing to environmental sustainability.